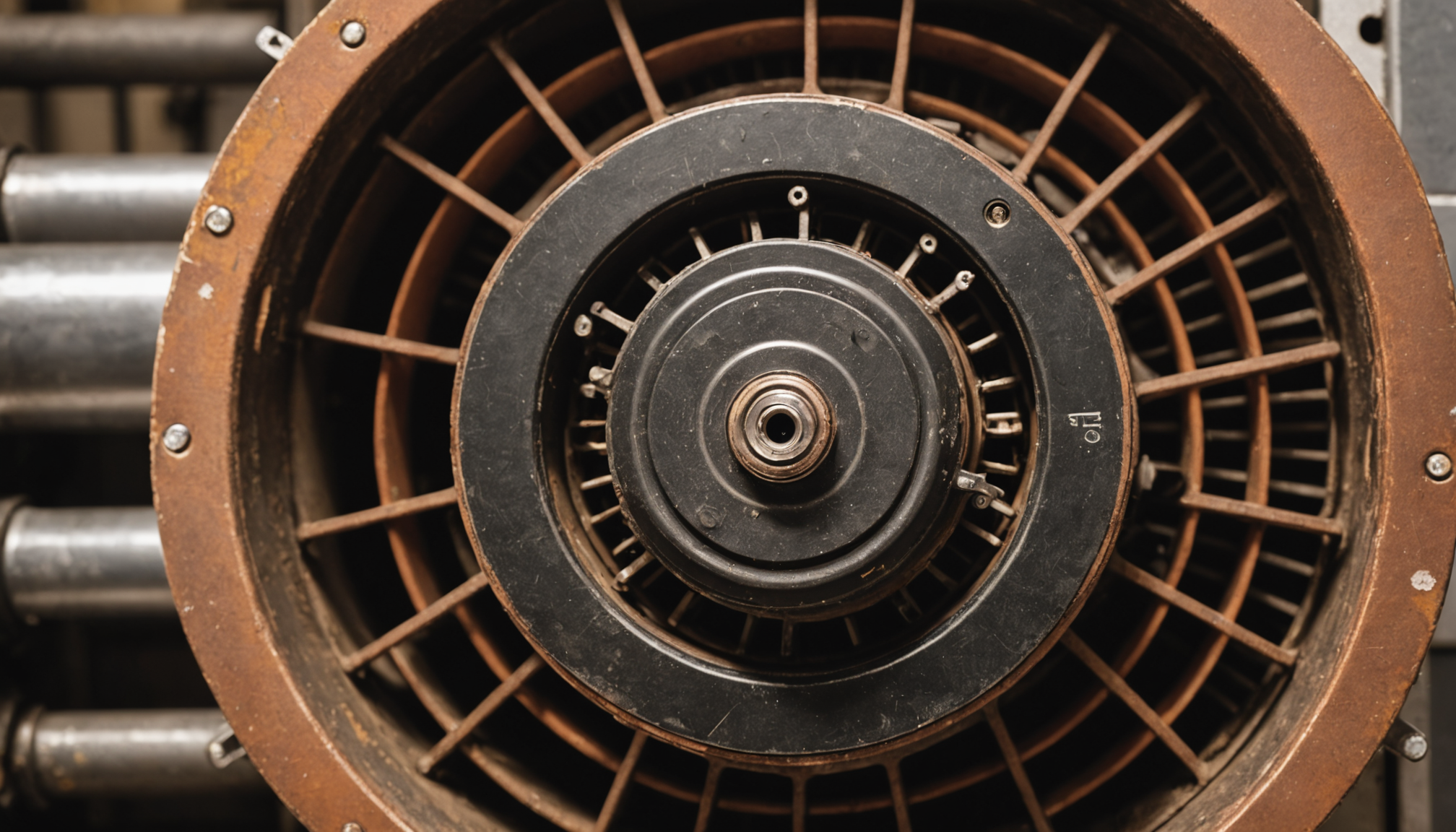

A blower motor is an essential component in HVAC systems, responsible for circulating air throughout your home to ensure a comfortable environment. However, like all mechanical devices, blower motors can wear out or fail over time. Recognizing the common signs of a failing blower motor can help you address the issue before it leads to more extensive and costly furnace repair or affects other HVAC components.

One of the most prevalent indicators of a blower motor issue is the presence of unusual noises. You may hear grinding, squealing, or rattling sounds when the system is operating. These noises often suggest that there may be worn bearings, a loose belt, or debris lodged in the motor or fan. Addressing these noises promptly can prevent further damage and extend the life of the blower motor.

Another sign of potential blower motor problems is inconsistent airflow throughout your home. If some rooms are warmer or cooler than others, it might be due to the blower motor not functioning at its full capacity. Reduced airflow can lead to inefficient heating or cooling, ultimately driving up energy costs and reducing comfort levels. Pay attention to any unusual variations in air distribution, as they can be an early warning of motor inefficiency.

In addition to noises and airflow issues, frequent cycling on and off of the HVAC system may indicate that the blower motor is struggling. This symptom, known as short cycling, not only affects your comfort but can also lead to increased wear and tear on the unit.

Another key warning sign is an increase in your energy bills without a corresponding increase in HVAC usage. A failing blower motor often requires more energy to produce the same level of air circulation, which can reflect in higher electricity costs.

Below is a comparison table that outlines various signs of a failing blower motor and their potential implications:

| Sign | Potential Implication |

| Unusual Noises | Worn bearings, loose components, or debris in the system |

| Inconsistent Airflow | Inefficient heating/cooling, potential motor inefficiency |

| Frequent Cycling | Overworking of the motor, increased wear |

| Higher Energy Bills | Reduced efficiency, requiring more energy for operation |

Understanding these common signs and acting proactively can save you from unexpected furnace repair costs and ensure that your HVAC components are running smoothly and efficiently. Regular maintenance and prompt attention to these warning signs increase the likelihood of catching problems early, allowing for a more cost-effective and timely resolution.

unusual noises to listen for

When it comes to identifying the unusual noises that may indicate a deteriorating blower motor, it is crucial to be observant and attentive to your HVAC system’s sounds. Here’s a step-by-step guide to help you identify these noises and understand what they might signify:

1. Grinding Sounds:

– What to Listen For: A consistent grinding sound, likened to metal-on-metal, could be a sign of worn ball bearings within the motor.

– What It Indicates: This noise typically suggests that the motor bearings are down, possibly due to age or lack of lubrication. If ignored, it could lead to motor burnout and expensive furnace repair.

– Action Steps: If you hear this noise, it’s crucial to address it immediately, either by lubricating the bearings if possible or considering a professional assessment to prevent a complete motor failure.

2. Squealing or Screeching:

– What to Listen For: A high-pitched squeal or screech, often most notable when the system starts, pauses, or turns off.

– What It Indicates: This sound suggests that a belt connected to the blower motor might be loose or worn out. Additionally, it could be due to motor shaft misalignment.

– Action Steps: Inspect the belt for signs of wear or looseness. Replacing a worn belt or adjusting tension may resolve the issue. If the sound persists, professional inspection is recommended to prevent additional stress on the HVAC components.

3. Rattling Noises:

– What to Listen For: A rattling or clattering noise, which might occur in tandem with operation and ceases when the system is off.

– What It Indicates: This could point towards loose components or debris trapped within the motor or fan assembly. It’s also possible that some parts have come free during operation.

– Action Steps: Safely shut down the system and inspect for visibly loose parts or debris in the system. Secure any loose components and remove debris if possible. Persistent rattling should be addressed by a technician to mitigate risk.

4. Humming or Buzzing:

– What to Listen For: An unusual humming, buzzing, or low droning sound that might be more noticeable as ambient noise increases.

– What It Indicates: Humming can indicate an electrical issue, possibly stemming from a failing capacitor or motor winding problems. Buzzing might also emerge from an imbalanced blower wheel.

– Action Steps: Considering the potential electrical fault, it’s safer to seek professional assistance. Attempting DIY fixes on electrical components can be hazardous.

Proactively listening for these noises and understanding their implications on your blower motor can help minimize further damage and costly repairs. Timely interventions are vital in prolonging the life of your blower motor and ensuring the overall efficiency of your HVAC system.

inconsistent airflow issues

Uneven heating or cooling in different areas of your house is a classic symptom of inconsistent airflow, suggesting potential issues with your HVAC system’s blower motor. When a blower motor fails to operate efficiently, it can hinder the even distribution of air, causing some rooms to feel noticeably warmer or cooler than others. Such disparities are not just about comfort; they indicate that your system may be working harder than necessary, which can accelerate wear and lead to costly furnace repair.

Inconsistent airflow is problematic because it impacts the overall performance of the HVAC components. For instance, if you find yourself adjusting thermostats or blocking vents to balance temperatures, it may reveal that the blower motor isn’t pushing out air with the pace and pressure required. This often results from a malfunctioning blower motor that struggles to maintain a consistent output, causing certain areas in your home to be underserved while others receive too much air.

Another common sign is the reduction in airflow coming from the vents, even when you know the system is set to a high operational level. This reduced airflow might be barely noticeable or significant enough to affect your comfort, like making your furnace less effective in the cooler months or the air conditioning less efficient in summer heat. Regardless of the extent, diminished airflow almost invariably suggests your blower motor requires attention, perhaps due to a failing motor, obstructed ducts, or issues like blockages within the system itself.

Besides direct comfort implications, inconsistency in airflow can lead to higher energy consumption. When the blower motor is inefficient, your HVAC system tends to run longer cycles or more frequently as it attempts to maintain your desired home climate. This not only burdens the motor but also reflects in heightened energy bills, since the system pulls more power to compensate for its inefficiencies.

By promptly addressing inconsistent airflow issues, you can ensure your HVAC components work optimally, reducing strain on the blower motor and lowering risks of sudden breakdowns. Early detection and management of these airflow irregularities are key to extending the lifespan of your furnace and avoiding unplanned outages and repair costs.

inspection and testing methods

To properly inspect and test a blower motor, you’ll want to start by ensuring the HVAC system is turned off and, if possible, unplugged to prevent any electrical hazards. Begin with a visual inspection: look for any obvious signs of wear or damage on the blower motor itself, as well as on the surrounding HVAC components. This includes checking for rust, burns, or any loose and worn-out wires which could signal electrical issues that may lead to further complications if ignored.

After the visual assessment, you should check the motor’s rotation. Manually spin the blower wheel (or fan) to see if it moves freely. Difficulty in movement might suggest bearing issues or obstructions. Ensure that there are no foreign objects lodged in the blower wheel that might be causing resistance. Additionally, listen for any scraping or grinding noises during this step, as they can indicate internal damages or the need for lubrication.

Electrical testing provides in-depth insights into the blower motor’s health. Use a multimeter to test the motor’s electrical connections. Measure the resistance (ohms) across the motor to ensure it is within the manufacturer’s specifications. If the readings are outside the normal range, the motor might be failing and could need replacement. Pay attention to continuity checks in the wires to identify shorts or open circuits, which can cause operational inefficiencies and unexpected system shutdowns.

For a more advanced inspection, you might test the motor’s voltage and amperage while the system is running, though this is typically advised for those with enough experience or professionals due to its complexity. These measurements can reveal if the motor is drawing more power than usual, a signal that it’s working harder than necessary and may soon require repair or replacement.

Inspecting the capacitor is another crucial step; a weak or faulty capacitor can prevent your blower motor from starting or running efficiently. Use a multimeter to measure the microfarads of the capacitor against the specifications indicated on its label. If there’s a substantial difference, replacing the capacitor might restore the motor’s functionality without needing more extensive furnace repair.

Lastly, consider whether the motor has potential blockages in the air ducts that could be impeding airflow. Even if the motor is functioning fine, blockages can force it to work harder, leading to premature wear. This is where duct cleaning can play an integral role in maintenance.

Being thorough in your inspection and testing methods not only helps in accurately diagnosing issues with your blower motor but also extends the lifespan of your HVAC components and can preempt costly furnace repair. Knowing how to conduct these inspections empowers you to make more informed decisions about potential repairs or the need for professional help, ensuring the optimal performance of your home systems.

when to seek professional help

When considering whether to enlist the help of a professional for your blower motor issues, there are a few key factors to keep in mind. First, if you’ve gone through the inspection and testing methods and haven’t identified the problem — or if the issue seems more serious than you can handle — it’s wise to call in a technician skilled in HVAC components. These professionals have the expertise to diagnose complex issues efficiently and safely, potentially saving you from more costly furnace repairs in the future.

Additionally, certain repairs, like those involving electrical components or intricate motor replacements, might pose risks if handled improperly without the right tools or comprehensive knowledge. Professionals are trained to manage these situations, ensuring that your HVAC components are not only repaired correctly but also tested to work efficiently after the fix. Furthermore, if you notice persistent issues despite taking initial steps, or if you lack the time to conduct thorough inspections, contacting a professional can prevent exacerbating the issue and lead to a quicker resolution.

When dealing with potential blower motor failure, the key is to act quickly. Delaying repairs can result in compounded damage to the system, leading to greater energy consumption, higher utility bills, and eventual breakdowns that could leave your home uncomfortable. Professional specialists can help mitigate this risk by performing thorough examinations and providing precise solutions tailored to the unique intricacies of your HVAC system.

Recognizing when to seek professional assistance remains a crucial step in maintaining a well-functioning blower motor and extends the lifespan of your furnace by addressing issues before they escalate. Whether it’s due to unexpected noises, airflow inconsistencies, or more severe functionality problems, a professional’s expertise can ensure the safe and effective operation of your system, preempting the need for more extensive furnace repair.

In conclusion, being familiar with the symptoms of a failing blower motor and taking prompt action can save you both time and money. From listening for unusual noises to inspecting for airflow issues and knowing when professional help is necessary, staying proactive with your HVAC system maintenance ensures optimal performance and comfort in your home.